Planet Earth is a legacy from the past to the present and our legacy for the future

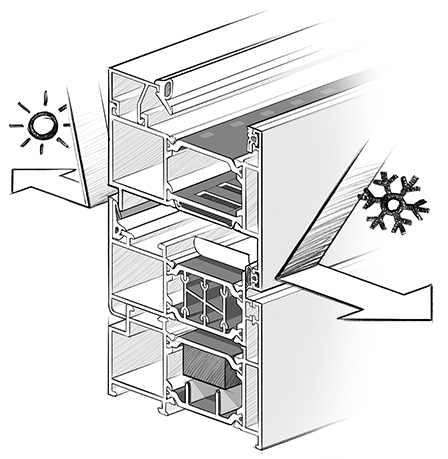

Aluminum doors, windows and facades are increasingly popular all over the world, but the main weakness of these windows is that they are not insulated from heat. To eliminate this defect, experts and specialists in the aluminum industry design and produce new types of profiles. They have made an aluminum called thermal break. Thermal break double glazed aluminum window, as its name implies, is a type of heat-insulating window.The heat transfer coefficient in aluminum is very high and for this purpose, aluminum profiles in this type of windows are connected to each other by polyamide strips. Polyamide strips have a composition with high pressure and heat resistance that prevents the transfer of heat and cold and can withstand temperatures up to 220 degrees and 50 degrees Celsius, creating a kind of barrier by resisting heat flow. Thermal-brake systems use the mechanism of sewing polyamide strips between the outer and inner walls of the frame and hinges to prevent the transfer of heat energy from the inside to the outside and vice versa and prevent heat and cold loss of the building.

In addition, the aluminum thermal break window is a type of sound insulation that prevents the transmission of noise into the building. Another point in the thermal break door and window system is the alignment of the longitudinal expansion coefficient of polyamide with aluminum in different weather conditions.If thermal break system is used on doors and windows, 38% reduction of thermal energy loss in cold season and 32% reduction of refrigeration energy loss in hot season, 28% reduction of fuel consumption, 20% reduction of cost in initial investment of facilities and also Noise pollution is significantly prevented and this is exactly the most important point that has been raised in Article 19 of the National Building Regulations regarding energy saving, the mission of Ata Polymer Company as a manufacturer of polyamide insulation strips, Consume energy and help prevent further waste.